Manufacturing Process

Every transport application places unique demands on the trailer, which is why every SDC Trailer is custom manufactured in line with our customer’s requirements.

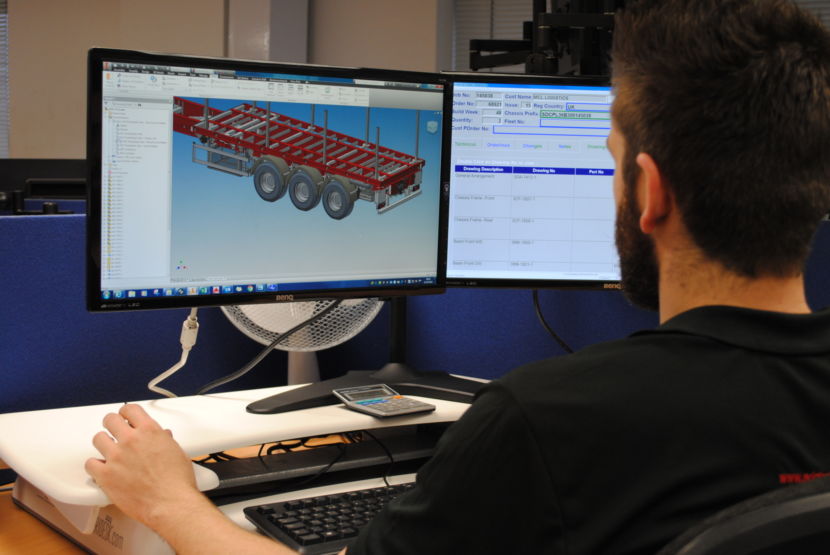

Design

From the beginning of the trailer ordering process, the customer is intrinsically involved. Regional Sales Managers liaise with the customer regarding the specification of the trailer that is best suited to meet their operations. The engineer, using various design tools, including the latest 3D solid modelling and stress analysis software creates a detailed sales drawing reflective of the customers specification. The flexibility in our resources allows for this drawing to be altered to achieve the right specification. When all stakeholders involved are certain this is the correct design to suit the customers operations, the design is then ready for production.

Fabrication

During the design process DXF files are created by our engineering team to facilitate parts to be cut directly on the latest CNC laser and plasma profile machines. Following the laser cutting process, where it is relevant, parts are pressed on the latest CMC press brakes. The accuracy of these machines achieves precisely cut metalwork ensuring a perfect fit. We utilize a wide range of welding techniques including state of the art robotic welding equipment which delivers unrivalled speed, precision and efficiency.

Chassis Preparation

All chassis undergo a fully automated shot blasting process. This achieves a clean, peened, smooth surface ready for paint application. This process is critical to the overall paint finish.

Paint

Our trailer units set the standard in terms of appearance and long-term durability. Using a technologically advanced 2 pack Epoxy Primer and Top Coat paint product over a fully shot blasted and pre-drilled chassis frame, our trailers will look good longer and enhance residual values. Our EHS Turbo Plus paint gives a finish of outstanding gloss and durability, to meet the highest standards required by fleet operators.

Assembly

The body is bolted to the chassis rather than welding it which avoids breaking the paint seal and adding to the life of the trailer. This allows for easy accident repair, meaning the trailer is off the road for the minimum period, saving time and money.

Quality Control

Every new SDC trailer is fully inspected by our team of quality engineers before being dispatched. Electronics, suspension and braking systems are tested using the latest computer diagnostic software.